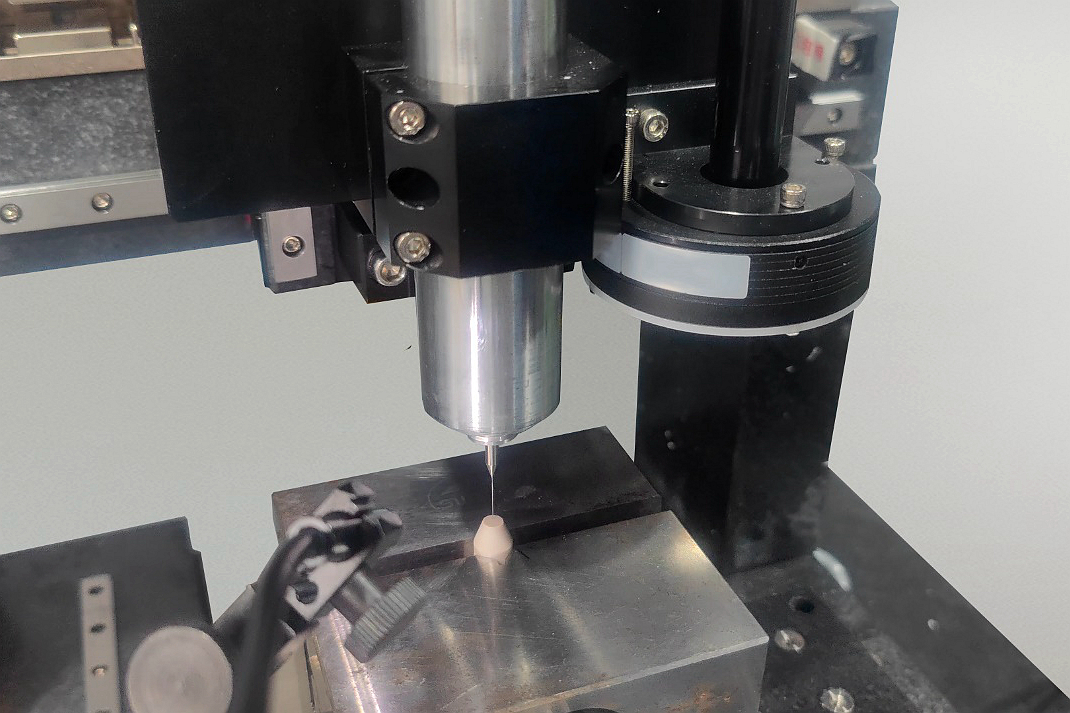

Precision Deep Hole Drilling Service

Our Precision Deep Hole Drilling Service provides accurate, high-quality drilling for deep, narrow holes in materials like metal and alloys. Using advanced equipment, we achieve tight tolerances, smooth surfaces, and efficient aspect ratio 50:1 to 100:1 hole depths.

- Rapid Drilling Prototyping Service

- Low Volume CNC Drilling Service

- CNC Drilling Mass Production Service

- One Stop CNC Drilling Service

Upload Your Design for Free Instant Quote

All uploaded files are secure and confidential

CNC Vs EDM Deep Hole Drilling

Our CNC & EDM Deep Hole Drilling Service combines precision machining with electrical discharge technology to achieve deep, narrow holes with exceptional accuracy. Ideal for hard-to-machine materials, it ensures high-quality results, tight tolerances, and smooth finishes for demanding applications.

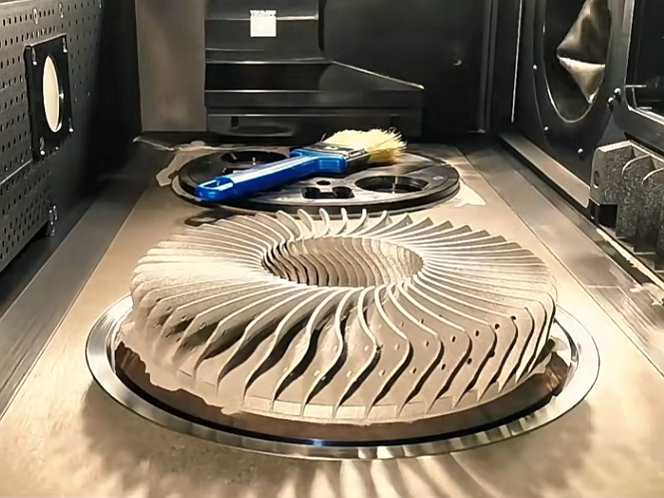

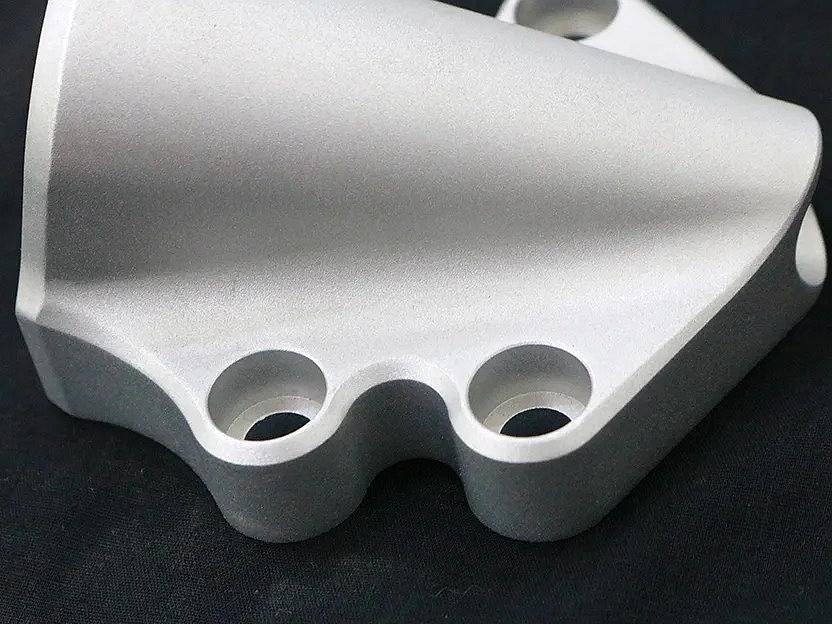

CNC & EDM Deep Hole Drilling Applications

CNC & EDM Deep Hole Drilling Applications cover various industries, providing precision drilling for components like turbine blades, fuel injectors, and hydraulic passages. This process ensures tight tolerances, smooth finishes, and optimal performance for complex, deep-hole requirements.

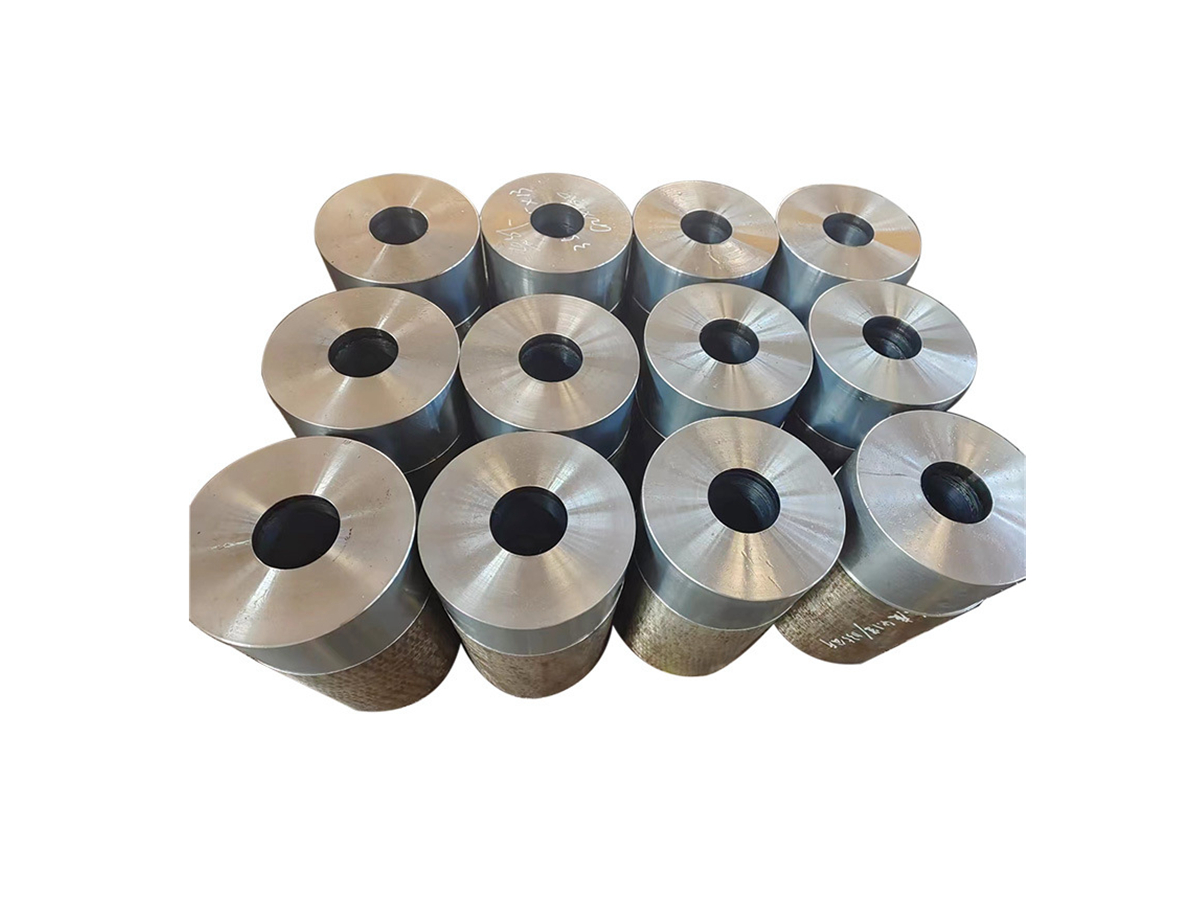

Key Materials for Precision CNC Drilling

CNC drilling is essential for precision machining of various materials, including superalloys, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastics, and ceramics. Each material offers unique characteristics, such as strength, corrosion resistance, and machinability, making them suitable for different industries. CNC drilling ensures high-quality, accurate cuts and holes for complex applications in manufacturing, aerospace, automotive, and more.

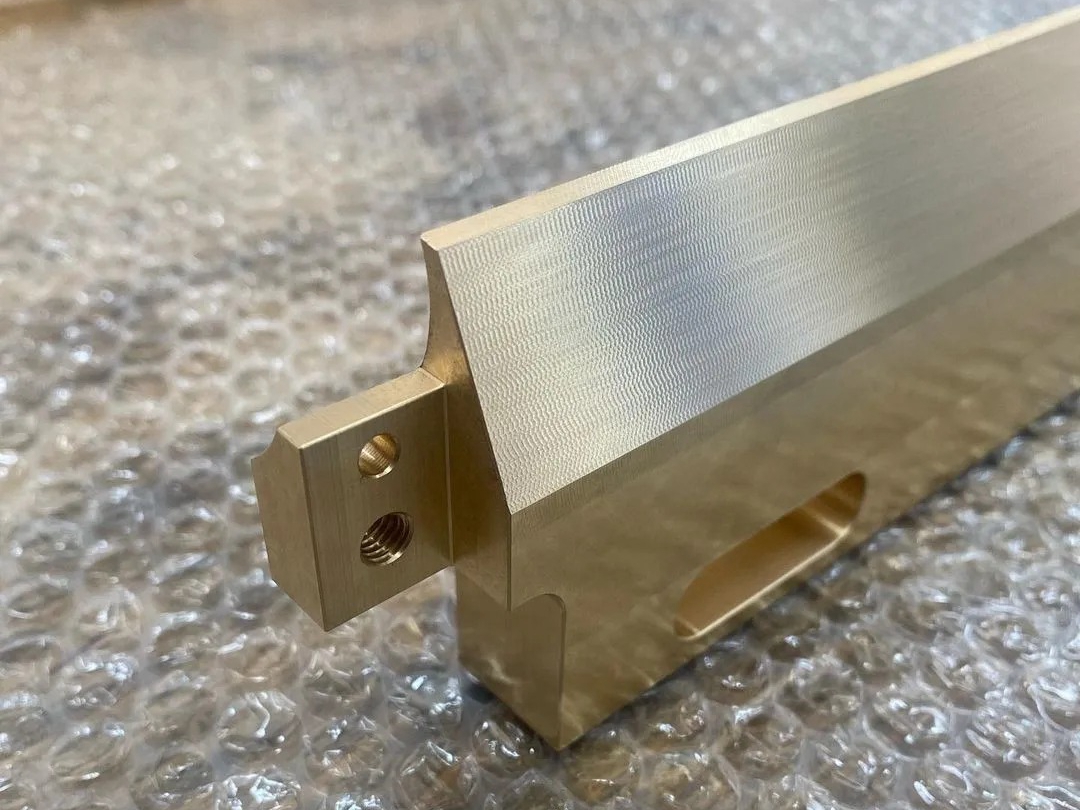

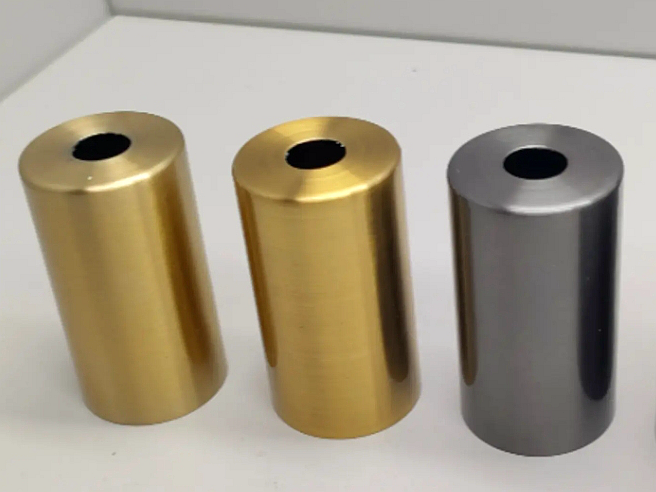

Surface Finishings CNC & EDM Deep Hole Drilling Parts

Surface Finishings for CNC & EDM Deep Hole Drilling Parts enhance part durability and functionality. We offer a variety of finishes, including polished, ground, or smooth surfaces, ensuring tight tolerances, minimal friction, and optimal performance for precision components.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

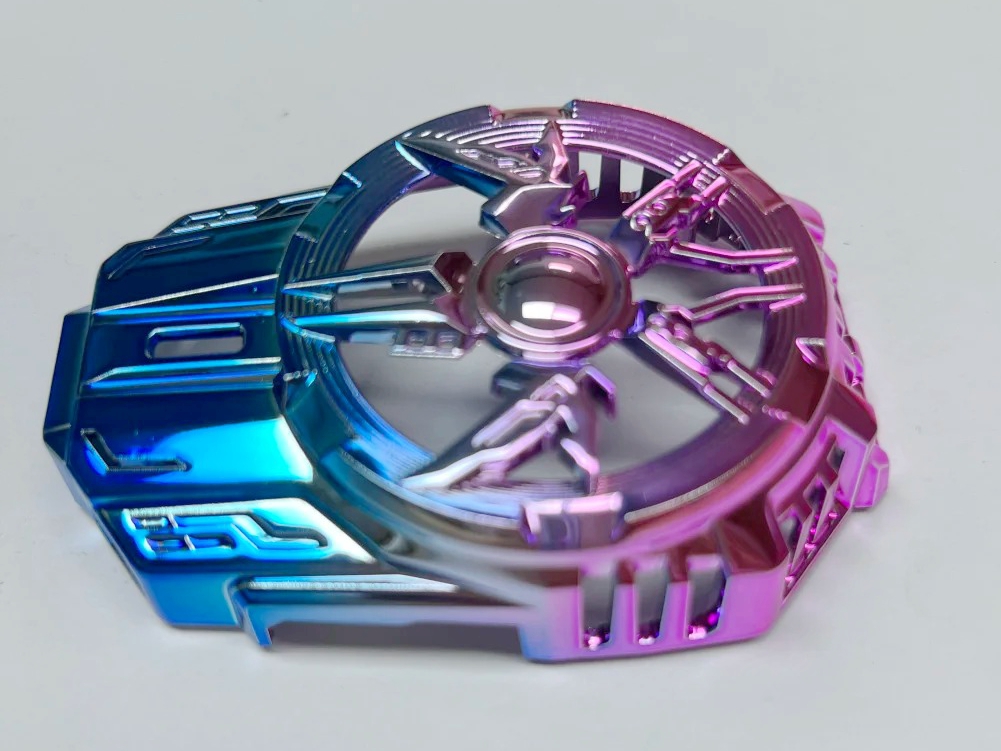

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

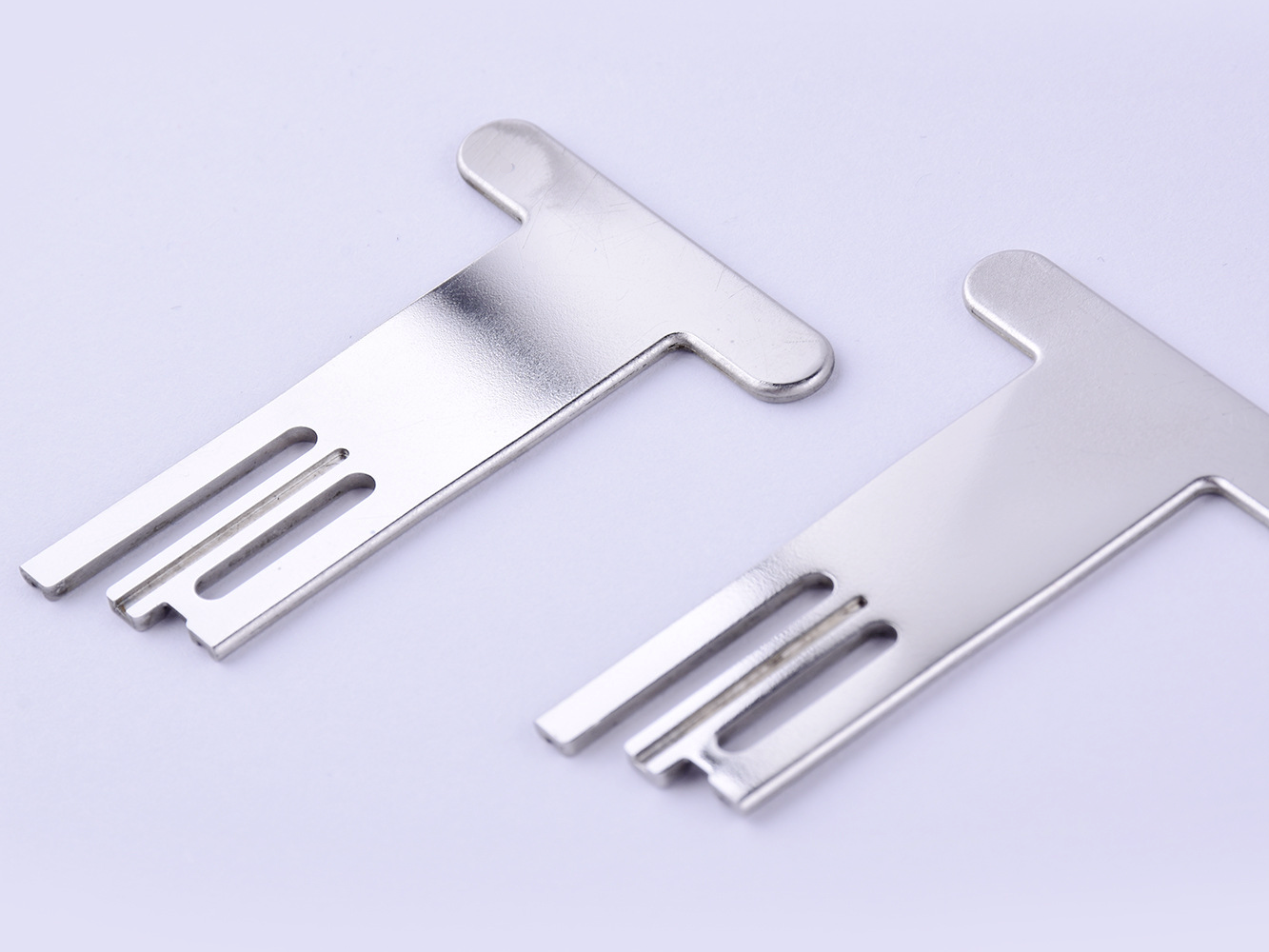

CNC & EDM Deep Hole Drilling Case Study

Our CNC & EDM Deep Hole Drilling Case Study highlights successful projects across various industries, showcasing how precision drilling techniques achieve tight tolerances, improve part performance, and meet complex design requirements. Explore our proven solutions for challenging deep-hole applications.

Let's Start A New Project Today

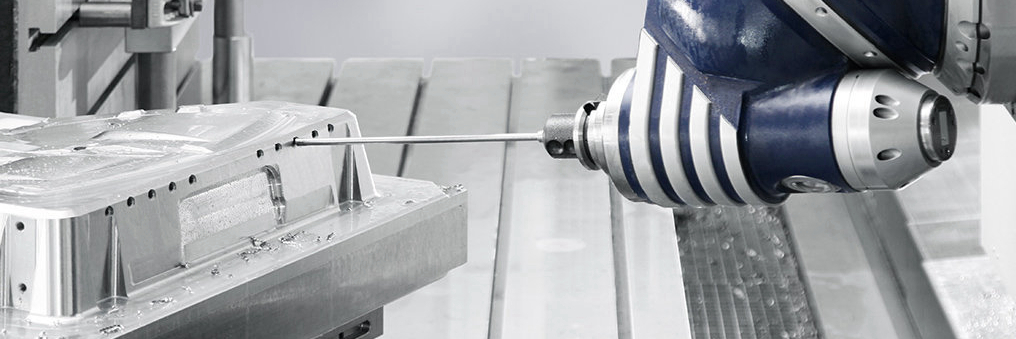

CNC & EDM Deep Hole Drilling Tolerance Suggestion

CNC & EDM Deep Hole Drilling Tolerance Suggestions provide guidelines for achieving precise, high-quality results. For standard applications, tolerances of ±0.1 mm are typical, while precision drilling can achieve ±0.02 mm to ±0.05 mm, depending on the complexity and material.

CNC & EDM Deep Hole Drilling Design Guideline

CNC & EDM Deep Hole Drilling Design Guidelines ensure precision and efficiency in creating complex holes. Recommendations include optimal radii, hole design ratios, thread specifications, and surface finishes, helping achieve tight tolerances and smooth, high-quality results across various applications.